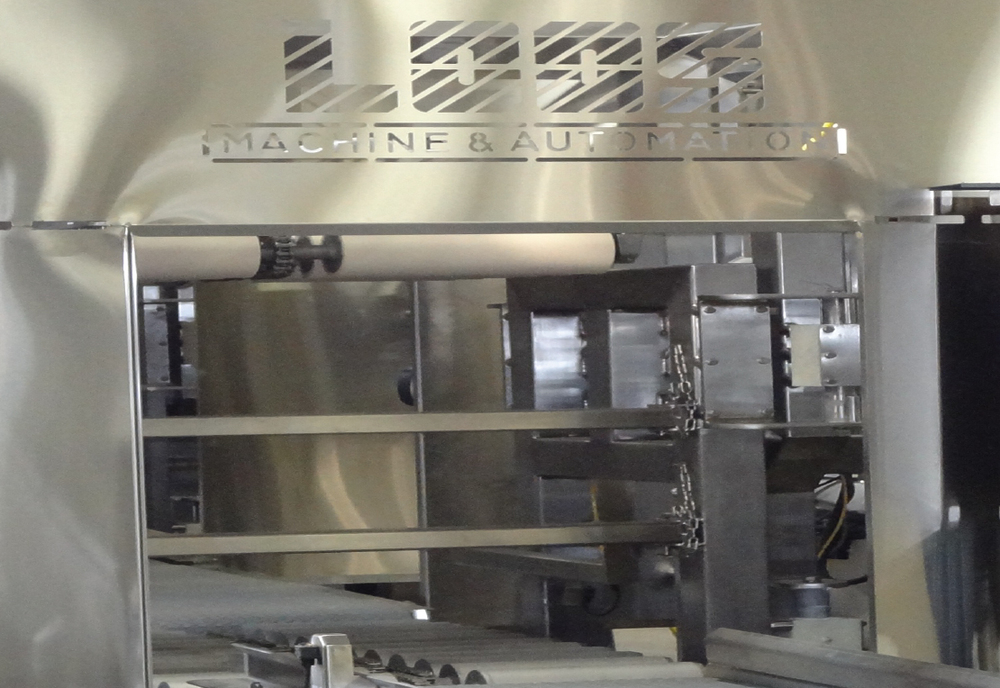

Our System

Loos Machine’s extensive knowledge and experience in producing 640 lb. blocks, 500 lb. barrels, etc. has allowed us to work directly with our customers to design custom systems for their specific quality cheese types.

Features

1 stop shop

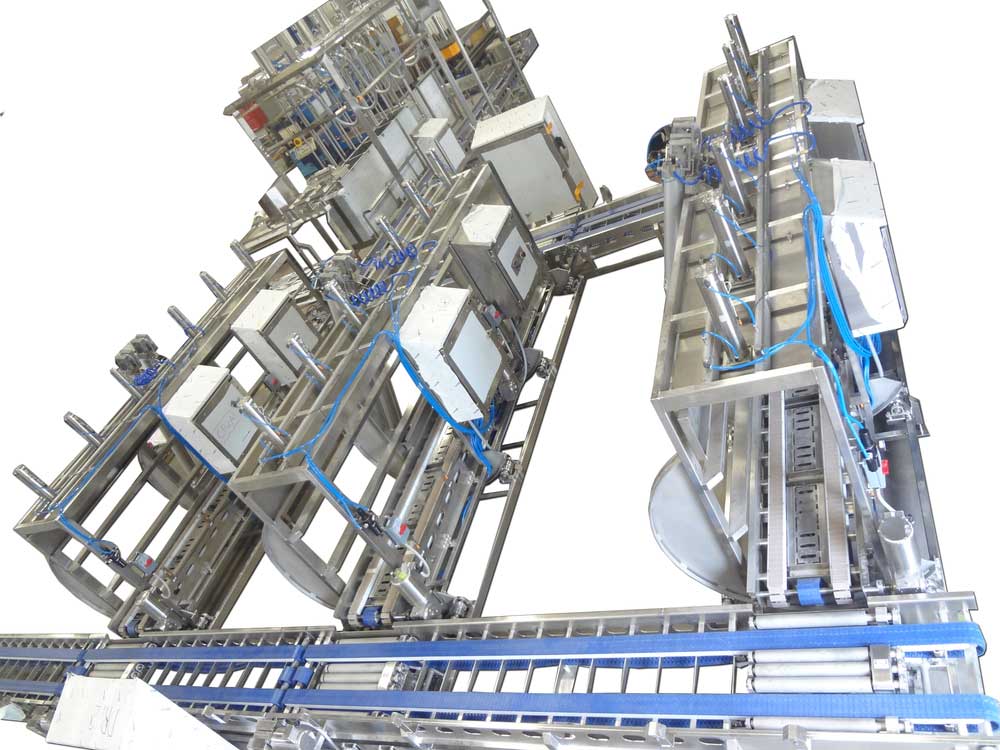

Efficient, compact systems, designs and layouts

Labor reduction

Maximize production throughput and yield

Integration at any point in the process

Long-lasting product equipment design

Unique transferring/phasing conveyor systems

Complete automated system to reduce labor

Easy to operate touch screen controls

Durability and quality of equipment

Turn-key with complete automated options

Components easily integrate with existing cart systems