Our System

Enjoy our quality cheese process turn-key systems which include everything from product de-boxing, handling, grinding, cooking, and more!

Features

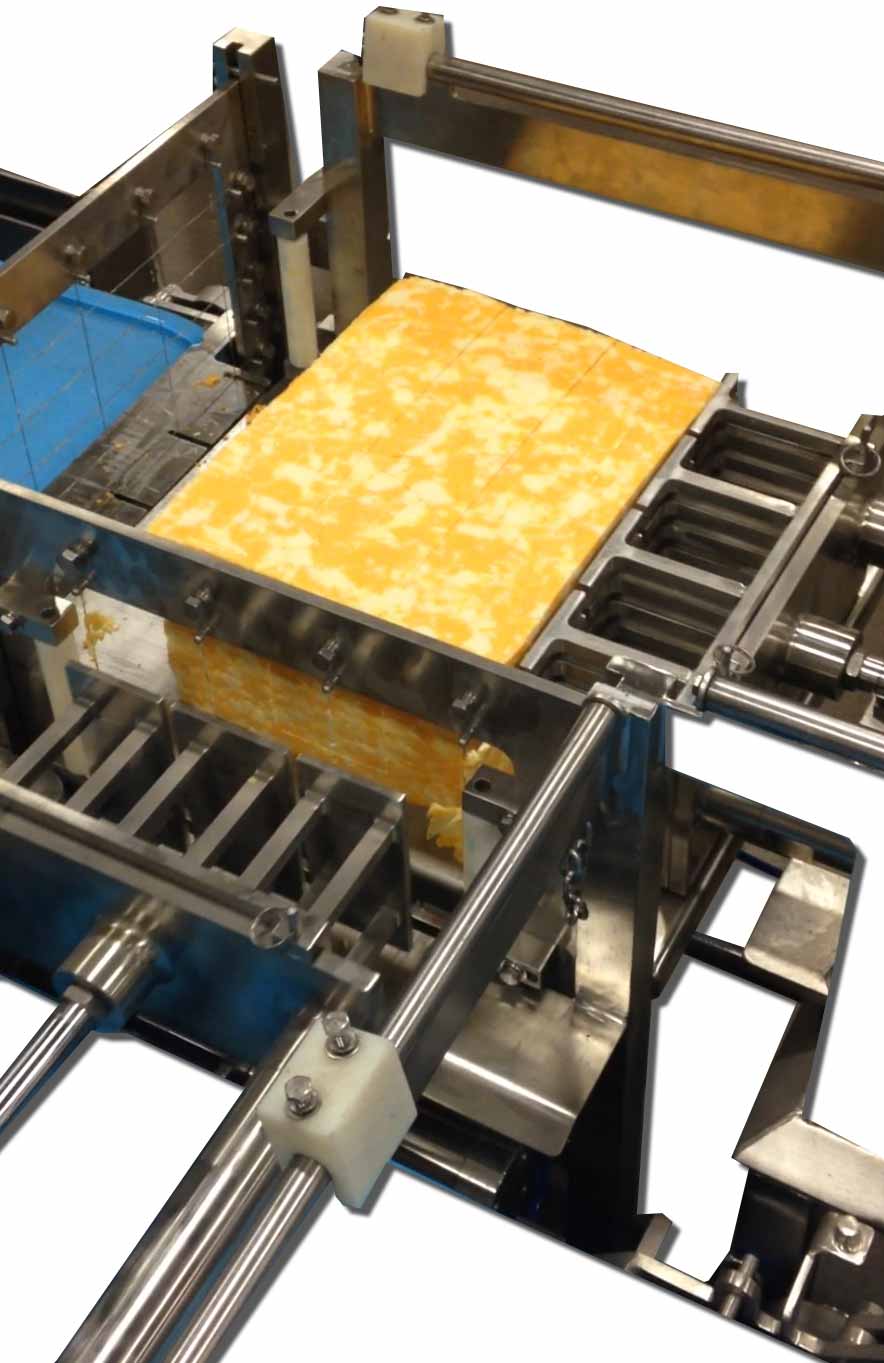

- De-Package barrels and blocks for grinder infeed

- Automated cheese recipe and ingredient delivery

- Custom designed grinders, mixers, cookers, to meet customers high throughputs

- Sanitary robust designs that are CIP-able

- Operator cost savings and labor reduction

- Efficient compact equipment footprints to maximize floor space