Transforming the dairy industry

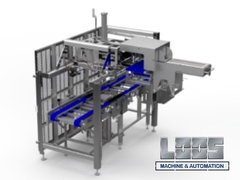

Loos Machine & Automation is transforming the dairy industry with its advanced, fully automated 40 lb. block, 640 lb. barrel, and 500 lb. barrel cheese systems. Designed for world-class cheese manufacturers, these state-of-the-art solutions ensure maximum efficiency, sanitation, and product consistency—key priorities in dairy production.

From fill stations and inverters to vacuum chambers and automated banding systems, Loos delivers end-to-end automation tailored to meet the demands of high-volume cheese processing. Our Clean-In-Place (CIP) capable equipment, including cyclone fill stations and press/probe systems, supports the rigorous hygiene standards essential in dairy facilities. These innovations help minimize labor, reduce contamination risk, and increase throughput.

For cheese processors handling large-format blocks and barrels, Loos offers custom solutions such as automated barrel palletizers, scale and labeling stations, and natamycin spraying units for mold prevention—ensuring quality and compliance at every stage. Their technologies not only streamline production but also enable processors to scale operations with reliability and precision.

In a dairy industry focused on automation, food safety, and operational excellence, Loos Machine & Automation stands out as a trusted partner. With decades of expertise and a commitment to innovation, Loos is helping shape the future of cheese manufacturing, one automated system at a time.

To view the original article, click here.

To view our listing on NDSFA, click here.

Blog Categories

Recent Articles

-

Cheese Processing, Engineered End-to-End

Feb 12, 2026

-

ISO 9001 Certification

Feb 06, 2026

-

Minimize Downtime

Nov 25, 2025

Blog Archives

Contact Us

- Loos Machine & Automation Main Office

- pref 205 W Washington St Colby, WI 54421 United States

- pref [email protected]

- pref 1 (855) 364-4797