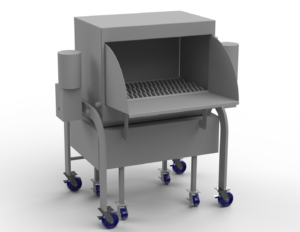

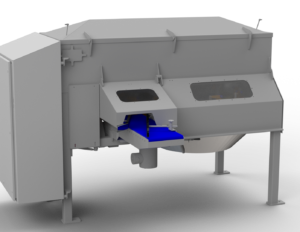

Cookers

Our Batch Cookers are perfect for high-volume cooking applications. Engineered for versatility, they can handle a variety of food products, providing uniform heat distribution for consistent results. With advanced temperature control and user-friendly interfaces, these cookers help streamline your production process while maintaining top-notch quality.

Sizes range from our compact 10 lb. lab scale cooker to our 4,000 lb. cooker.

Category: Process,Augured Equipment

Industry: Cheese/Dairy, Pizza/Bread, Fruit/Veggies, Meat/Poultry, Pet Food

Equipment Overview

Process cheese cookers are specialized industrial equipment used in the production of process cheese, which is cheese that has been modified to create a uniform product with a consistent texture, flavor, and melting properties.

These cookers perform several key functions:

- Mixing: They blend natural cheese with other ingredients such as emulsifiers, water, salt, and flavorings to achieve the desired consistency and taste.

- Heating: The mixture is heated to specific temperatures to melt the cheese and emulsify the ingredients. This step is critical for achieving a smooth and homogeneous product.

- Homogenizing: Some process cheese cookers also include homogenizing features to further refine the texture and ensure even distribution of ingredients.

- Cooking Control: Advanced cookers allow precise control over temperature and cooking time, ensuring consistent quality and preventing overcooking or burning.

Process cheese cookers are essential for producing a variety of processed cheese products, including slices, spreads, and sauces, offering efficient and scalable solutions for cheese manufacturers.

Equipment Gallery

Additional Information

Standard Features

Batch or continuous lay-down styles

Single or twin-screw models

Heat source: direct steam injection, heat induction, electric, etc.

Specially designed valves to maximize steam displacement

Heated and/or insulated jackets

Stainless steel bearing design

Finish options include polished to a #4 finish or glass beaded

Optional CIP-able product discharge valves

Meets WDA, USDA and FDA standards

WDA approved sanitary designed front and rear seals

Safety assessed and category rated

Automated Solutions

Automated batch recipe handling

Precise ingredient and emulsifier addition

Chart recording

Meets NEC, NFPA, and ANSI codes

UL approved

Optional Items

Single or twin screw

CIP-able

Jacketed auger

Load cells for precise recipe management