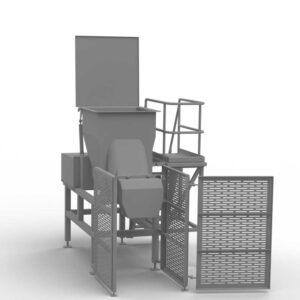

Grinders

Designed to accommodate various types of capacities and applications.

Can handle products ranging from 40 lb. to 640 lb. blocks, 500 lb. barrels, and totes.

Category: Augured Equipment

Industry: Cheese/Dairy, Pizza/Bread, Fruit/Veggies, Meat/Poultry, Beverage, Pet Food

Equipment Overview

Industrial grinders used for cheese, fruit, vegetables, and meat are versatile machines designed to handle a wide range of food processing tasks. These grinders are essential in various food production environments, providing efficient and consistent results.

- Functionality: Industrial grinders are equipped with powerful motors and robust grinding mechanisms to process different types of food products. They can efficiently grind cheese, fruits, vegetables, and meat into desired sizes and textures, suitable for further processing or direct use.

- Versatility: These machines can be adjusted or customized with different blades and screens to achieve specific particle sizes and consistencies, making them suitable for diverse applications such as purees, sauces, ground meat products, shredded cheese, and more.

- Efficiency: Industrial grinders streamline the food preparation process by handling large volumes quickly and consistently. They reduce manual labor and increase production speed, which is crucial for meeting high demand in commercial food production.

- Hygiene and Safety: Designed with food safety in mind, these grinders are made from stainless steel and other food-grade materials that are easy to clean and sanitize. Safety features are also integrated to protect operators and ensure safe operation.

Industrial grinders for cheese, fruit, vegetables, and meat are indispensable in food processing, providing a reliable and efficient means to prepare ingredients for a wide range of culinary and commercial applications.

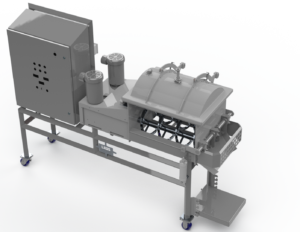

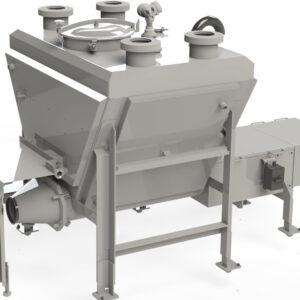

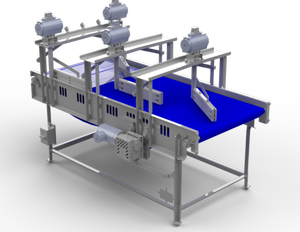

Equipment Gallery

Additional Information

Types

40 lb. to 640 lb. blocks and 500 lb. barrels.

Single and dual screw designs

Continuous flow or batch style

Single and dual screw designs

Continuous flow or batch style

Standard Features

Stainless steel construction

Optimal product reduction/custom particulate size discharge

Meets WDA, USDA, and FDA standards

Safety guarded

Various compact designs

Easily removable augers

Metered rates

Optimal product reduction/custom particulate size discharge

Meets WDA, USDA, and FDA standards

Safety guarded

Various compact designs

Easily removable augers

Metered rates

Performance

Various sizes available to accommodate required throughputs

Automated Solutions

PLC/HMI controls

Meets NEC, NFPA, and ANSI codes

UL approved

Weight control with load cells

Level and torque monitored

Meets NEC, NFPA, and ANSI codes

UL approved

Weight control with load cells

Level and torque monitored

Options

Mobile or stationary offering

Infeed/outfeed conveyance

Lifts and dumps pneumatic or hydraulic controlled

CIP-able equipment and bearing designs

Pre-breakers

Infeed/outfeed conveyance

Lifts and dumps pneumatic or hydraulic controlled

CIP-able equipment and bearing designs

Pre-breakers