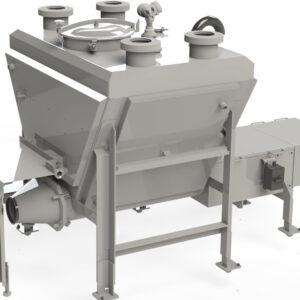

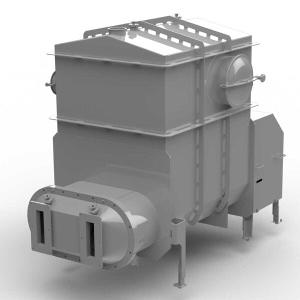

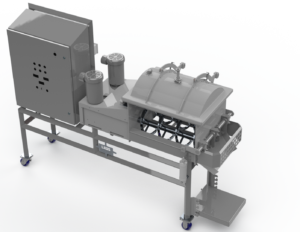

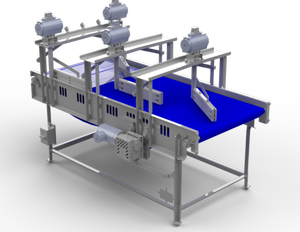

Surge Hoppers

With a wide variety of sizes, incorporate more storage and mixing capacity where needed in your plant process.

Surge hoppers are essential components in industrial processing and material handling systems, designed to manage and control the flow of bulk materials between different stages of production.

Category: Augured Equipment

Industry: Cheese/Dairy, Pizza/Bread, Fruit/Veggies, Meat/Poultry, Beverage, Pet Food

Equipment Overview

Surge hoppers are essential components in industrial processing and material handling systems, designed to manage and control the flow of bulk materials between different stages of production.

- Functionality: Surge hoppers act as temporary storage containers that regulate the flow of materials such as powders, granules, or small solids. They are strategically placed to collect material from one process and feed it consistently into the next, ensuring a smooth and continuous operation.

- Efficiency: By providing a buffer between processing steps, surge hoppers help to accommodate variations in material flow and production rates. This reduces downtime and prevents bottlenecks, enhancing overall process efficiency and productivity.

- Versatility: Surge hoppers are used in a wide range of industries, including food processing, pharmaceuticals, agriculture, and manufacturing. They can handle various materials and are often equipped with features like flow control valves, vibrators, and level sensors to optimize performance.

- Design and Safety: Constructed from robust materials such as stainless steel, surge hoppers are designed to withstand demanding industrial environments. They are also designed with safety features to prevent overflows and ensure safe operation.

Surge hoppers play a critical role in maintaining consistent material flow, improving operational efficiency, and ensuring the smooth functioning of complex industrial processes.

Equipment Gallery

Additional Information

Types

Various sizes available to accommodate required throughputs

Agitation completed utilizing augers or rotating scrapers

Designed to accommodate any desired pump(s)

Quality

Performance

Automated Solutions

Integrates easily with existing processing systems

VFD controlled agitation and pump speeds

Weight and level control feedback

Recipe integration

Meets NEC, NFPA and ANSI codes

UL approved

Optional Items

Insulation

Discharge pumps

Tank scrapers

Stainless steel baskets

Vacuum

CIP-able

Teflon coating