Inline Weighing Systems

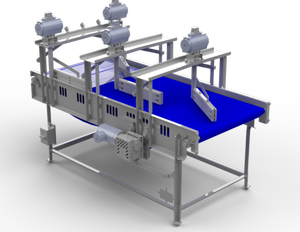

Our inline weighing system allows our customers to accurately measure the weight of independent or bulk products.

Discover how Loos Machine & Automation's Inline Weighing Systems can enhance your production process. Contact us today to learn more and request a personalized quote.

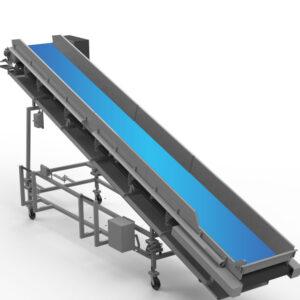

Category: Conveyors,Specialty Equipment

Industry: Cheese/Dairy, Pizza/Bread, Fruit/Veggies, Meat/Poultry, Beverage, Pet Food, Packaging

Equipment Overview

At Loos Machine & Automation, we understand the critical role that accurate weighing plays in your production process. Our Inline Weighing Systems are designed to deliver unparalleled precision and efficiency, ensuring that your products are weighed accurately and consistently as they move through your production line.

Key Features

- High Accuracy: Our systems use advanced load cells and sophisticated electronics to ensure precise weight measurements with minimal deviation. This accuracy helps you maintain product consistency and quality.

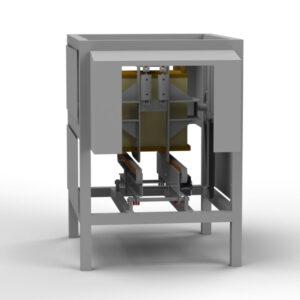

- Real-Time Monitoring: Equipped with intuitive interfaces and real-time data tracking, our Inline Weighing Systems provide instant feedback on weight measurements, allowing for immediate adjustments and corrections.

- Seamless Integration: Designed to fit seamlessly into existing production lines, our systems can be easily integrated with other equipment, minimizing downtime and optimizing workflow.

- Durable Construction: Built with high-quality materials and engineered for robustness, our weighing systems are capable of handling the rigors of industrial environments, ensuring long-term reliability and performance.

- Flexible Configurations: Whether you need to weigh bulk products, packaged goods, or anything in between, our Inline Weighing Systems can be customized to meet your specific requirements.

Applications

Our Inline Weighing Systems are ideal for a variety of applications, including:

- Food and Beverage Processing: Ensure accurate portion control and adherence to regulatory standards in the production of food and beverage products.

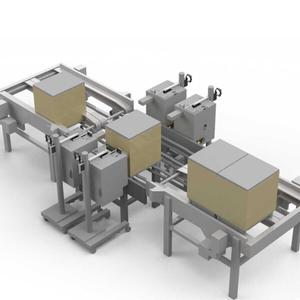

- Packaging: Improve packaging accuracy and reduce waste by ensuring correct product weights.

Why Choose Loos Machine & Automation?

- Expertise and Innovation: With years of experience in automation and weighing systems, we bring a wealth of knowledge and innovation to every project.

- Customer-Centric Approach: We work closely with you to understand your specific needs and provide tailored solutions that meet your exact requirements.

- Comprehensive Support: From initial consultation to installation and ongoing maintenance, our dedicated support team is here to ensure your systems operate flawlessly.

Equipment Gallery

Additional Information

Types

Bulk continuous product

Standard Features

Increase yield and eliminating waste of additives

Easy recipe and ratio changes with custom HMI recipe page

Easy applicator equipment integration

Continuous process solutions

High speed and precise accuracy

Quality

Washdown instrumentation

Automated Solutions

Meets NEC, NFPA, and ANSI Codes

UL Approved

3D vision control

Scanning verification & tracking