Labeling Systems

Our inline weighing system allows our customers to accurately measure the weight of independent or bulk products.

Category: Conveyors,Specialty Equipment,Robotics

Industry: Cheese/Dairy, Pizza/Bread, Fruit/Veggies, Meat/Poultry, Beverage, Pet Food, Packaging

Equipment Overview

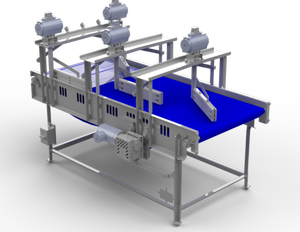

Our Inline Weighing & Labeling Systems are designed to enhance your production line with accurate, efficient, and reliable weighing and labeling capabilities. These systems are essential for industries where precision and traceability are critical, such as food processing, pharmaceuticals, and manufacturing. By seamlessly integrating weighing and labeling into your production process, you can ensure compliance with industry standards, reduce waste, and increase overall productivity.

Accurate Weighing for Quality Control

Accurate weight measurements are crucial for quality control, ensuring that each product meets specific weight requirements and complies with regulatory standards. Our inline weighing systems are equipped with advanced load cells and sensors that provide real-time, high-precision measurements. This ensures that every product passing through your production line is within the desired weight range, reducing the risk of under- or over-filling.

- High Precision: Advanced load cells provide accurate weight measurements with minimal deviation.

- Real-Time Data: Instant feedback allows for immediate adjustments, ensuring consistency and compliance.

- Customizable Settings: Easily adaptable to different product types and weight specifications.

Efficient Labeling for Traceability and Compliance

Labeling is a critical step in ensuring product traceability, compliance with regulations, and providing consumers with essential information. Our inline labeling systems are designed to apply labels quickly and accurately, even at high speeds. Whether you need to label individual items, cases, or pallets, our systems ensure that every label is correctly applied and easily readable.

- High-Speed Labeling: Capable of applying labels at high production speeds without sacrificing accuracy.

- Versatile Labeling Options: Compatible with various label sizes, formats, and adhesive types.

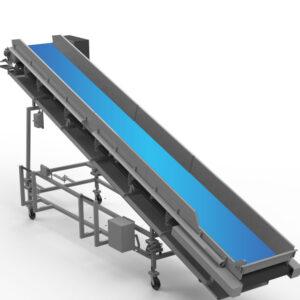

- Automated Integration: Seamlessly integrates with your existing production line, reducing manual intervention and increasing efficiency.

Integrated Weighing & Labeling for Streamlined Operations

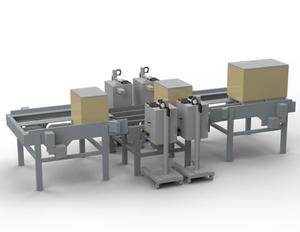

Combining weighing and labeling into a single, integrated system offers numerous advantages for your production line. Our Inline Weighing & Labeling Systems are designed to work together seamlessly, ensuring that products are accurately weighed and labeled in one continuous process. This integration reduces the need for separate equipment, minimizes manual handling, and increases overall throughput.

- Reduced Downtime: Streamlined operations lead to fewer interruptions and increased production efficiency.

- Compact Design: Our systems are designed to occupy minimal floor space while delivering maximum performance.

- User-Friendly Interface: Intuitive controls and real-time monitoring make it easy to operate and maintain the system.

Compliance and Reporting

In today’s regulatory environment, ensuring compliance with labeling and weight requirements is more important than ever. Our Inline Weighing & Labeling Systems provide detailed reporting and traceability features, allowing you to maintain complete records of every product processed. This not only helps you meet regulatory standards but also provides valuable data for optimizing your production processes.

- Regulatory Compliance: Ensure your products meet all industry standards for weight and labeling.

- Detailed Reporting: Access comprehensive data and reports for auditing and process improvement.

- Traceability: Maintain a complete record of product weight and labeling history for quality assurance.

Why Choose Our Inline Weighing & Labeling Systems?

At Loos Machine & Automation, we understand the importance of precision, efficiency, and compliance in your production line. Our Inline Weighing & Labeling Systems are engineered to deliver consistent, reliable performance, helping you maintain high standards of quality while optimizing your operations. Whether you’re in the food industry, pharmaceuticals, or manufacturing, our systems provide the integrated solutions you need to stay ahead in today’s competitive market.

Equipment Gallery

Additional Information

Types

Bulk continuous product

Standard Features

Increase yield and eliminating waste of additives

Easy recipe and ratio changes with custom HMI recipe page

Easy applicator equipment integration

Continuous process solutions

High speed and precise accuracy

Quality

Wash-down instrumentation

Automated Solutions

Meets NEC, NFPA, and ANSI Codes

UL Approved

3D vision control

Scanning verification & tracking