Palletizing

From robotic, Cartesian pick and place, and large same speed transition palletizers, we can handle a variety of products ranging from small boxes to large 4,000 lb. containers.

Category: Conveyors,Robotics

Industry: Cheese/Dairy, Pizza/Bread, Fruit/Veggies, Meat/Poultry, Beverage, Pet Food, Packaging

Equipment Overview

Our Palletizing Solutions are designed to automate and streamline the process of stacking products onto pallets, ensuring that your operations are efficient, accurate, and cost-effective. Whether you're handling boxes, bags, crates, or other types of packaging, our systems provide the flexibility and precision needed to optimize your production line. Ideal for industries such as food and beverage, manufacturing, logistics, and more, our palletizing systems help you meet the demands of high-volume production with ease.

Automated Palletizing for Increased Efficiency

Automation is key to improving throughput and reducing labor costs in any production environment. Our palletizing systems are equipped with advanced robotics and automation technology, allowing for consistent and high-speed stacking of products onto pallets. This not only enhances efficiency but also ensures that pallets are packed securely and uniformly, reducing the risk of damage during transportation.

- High-Speed Palletizing: Capable of handling large volumes of products quickly and accurately, ensuring a continuous flow of goods through your production line.

- Precision Stacking: Ensures that products are stacked evenly and securely, optimizing space and stability on each pallet.

- Flexible Configurations: Adaptable to various product sizes, shapes, and weights, with customizable stacking patterns to meet your specific needs.

Robust and Versatile Systems

Our palletizing solutions are designed to be versatile and durable, capable of handling a wide range of products and packaging types. Whether you need a system for small-scale operations or large industrial applications, we have the right solution for you. Our systems can be integrated with existing production lines, offering a seamless transition to automated palletizing.

- Versatility: Handles different types of packaging, including cartons, bags, cases, and more.

- Durability: Built to withstand the rigors of continuous operation in demanding industrial environments.

- Seamless Integration: Easily integrates with your existing equipment and processes, ensuring minimal disruption during implementation.

Custom Palletizing Solutions

Every production line is unique, and so are your palletizing needs. We offer custom solutions tailored to your specific requirements, whether you need specialized equipment, unique pallet patterns, or specific handling capabilities. Our team works closely with you to design and implement a palletizing system that fits perfectly within your operation, maximizing efficiency and productivity.

- Tailored Designs: Customized to fit your product specifications, production volume, and space constraints.

- Advanced Software: Includes intuitive programming and control systems that allow for easy setup, operation, and monitoring.

- Scalable Solutions: Designed to grow with your business, with options for expanding capacity and capabilities as needed.

Enhanced Safety and Ergonomics

Palletizing can be a physically demanding task, leading to potential safety hazards and worker fatigue. Our automated palletizing systems are designed with safety and ergonomics in mind, reducing the need for manual lifting and stacking. This not only enhances workplace safety but also improves overall efficiency by allowing your workforce to focus on higher-value tasks.

- Reduced Manual Handling: Automation reduces the risk of injury by minimizing the need for manual lifting and stacking.

- Safety Features: Equipped with safety sensors and guards to protect operators and ensure safe operation.

- Ergonomic Design: Improves working conditions by eliminating repetitive and strenuous tasks.

Why Choose Our Palletizing Solutions?

At Loos Machine & Automation, we understand the importance of efficient, reliable, and scalable palletizing solutions. Our systems are designed to meet the demands of modern production environments, providing you with the tools you need to stay competitive. Whether you're looking to automate a single process or overhaul your entire production line, our palletizing solutions offer the flexibility, durability, and performance you need to succeed.

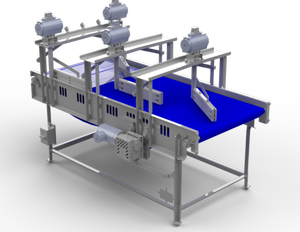

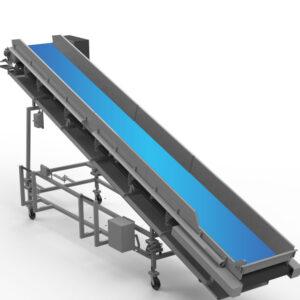

Equipment Gallery

Additional Information

Types

Robotic

Cartesian pick and place

Palletizers

Standard Features

Available sizes to accommodate products including powder totes, barrels, bags, boxes, crates, etc.

Fully automated

Includes pallet loaders

Include as many discharge conveyors or accumulation conveyors for sampling system

Can accept any size pallet

Wash-down friendly

Quality

Precise staging

Maximize warehouse space with accuracy

Automated Solutions

Integration with existing plant controls

Varying palletizing speeds

Robotics depending on container size

Meets NEC, NFPA and ANSI codes

UL approved

Optional Items

1, 2, 4, barrel nesting configurations

Integrates easily with stretch wrappers and existing handling systems

Printing/labeling solutions