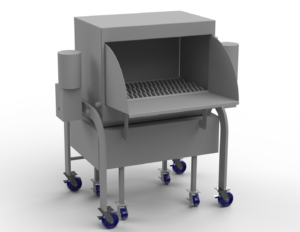

Product Return Systems

At Loos Machine & Automation, our Product Return Systems are designed to enhance operational efficiency by seamlessly integrating with existing production lines. These systems are critical for automating the return of rejected or off-spec products back into the processing stream for rework or redistribution.

Category: Conveyors,Augured Equipment

Industry: Cheese/Dairy, Pizza/Bread, Fruit/Veggies, Meat/Poultry, Pet Food

Equipment Overview

Every production line is unique, which is why we offer tailored solutions to meet your specific requirements. From small-scale operations to large-scale manufacturing, our engineering team works closely with you to design a system that optimizes your return processes.

Key Benefits:

- Streamlined Operations: Ensure continuous workflow by returning product to the start of the line without manual intervention, reducing downtime.

- Cost-Efficiency: Maximize material usage by reintroducing product into the line, minimizing waste.

- Quality Control: Maintain high-quality standards by isolating and redirecting off-spec products for reprocessing, ensuring only the best product moves forward.

- Custom Integration: Each system is customized to fit your production needs, offering flexibility across a wide range of industries, from food processing to packaging.

Standard Features:

- Automated Return Functionality: Our systems automatically detect and divert products, ensuring a seamless process without the need for manual intervention.

- High-Durability Construction: Built to withstand demanding production environments, ensuring long-term, reliable operation.

- Flexible Design: Designed to integrate with various conveyor systems and automation setups.

- User-Friendly Interface: Equipped with intuitive controls and monitoring systems for easy operation and real-time adjustments.

- Sanitary Design Options: For food and beverage industries, our product return systems are designed with hygiene in mind, meeting stringent sanitation standards.