Re-Weigh Systems

Our Re-Weigh Systems are designed with your needs in mind, offering reliable performance, easy integration, and customizable features that ensure your products meet the strictest quality standards. Trust our systems to help you maintain precision, reduce waste, and enhance customer satisfaction in every batch you produce.

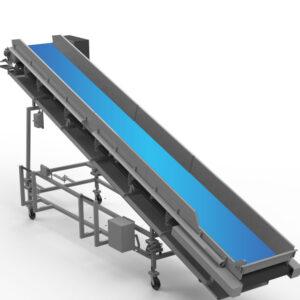

Category: Conveyors

Industry: Cheese/Dairy, Pizza/Bread, Fruit/Veggies, Meat/Poultry, Beverage, Pet Food, Packaging

Equipment Overview

In industries where precision is paramount, our Re-Weigh Systems provide a crucial layer of accuracy and quality control. Designed to verify product weights post-packaging, our systems ensure that each item meets the specified weight requirements before it reaches the next stage of production or distribution. Ideal for food processing, manufacturing, and logistics, our Re-Weigh Systems help you maintain compliance with industry standards while minimizing product waste and maximizing customer satisfaction.

Precision Weighing for Quality Assurance

Our Re-Weigh Systems are engineered to deliver high-precision weight measurements, ensuring that your products consistently meet weight specifications. Whether you’re verifying individual items, cartons, or pallets, our systems provide reliable and repeatable results, helping you catch discrepancies early and maintain product consistency.

- High Accuracy: Advanced sensors and load cells provide precise weight measurements with minimal variation.

- Consistent Quality Control: Ensures that every product meets weight requirements, reducing the risk of under- or over-weight items reaching customers.

- Real-Time Adjustments: Integrated feedback mechanisms allow for immediate corrections, maintaining accuracy throughout your production run.

Integrated Solutions for Seamless Operation

Our Re-Weigh Systems are designed to integrate seamlessly into your existing production line, minimizing disruption while enhancing overall efficiency. These systems are equipped with user-friendly interfaces and automation features that streamline the re-weighing process, allowing for quick and easy setup, operation, and monitoring.

- Easy Integration: Compatible with a wide range of production equipment and processes, ensuring smooth implementation.

- Automated Operation: Reduces manual handling and improves throughput with automated weighing and feedback loops.

- User-Friendly Interface: Intuitive controls and real-time data displays make it easy to monitor system performance and make adjustments as needed.

Customizable for Diverse Applications

We understand that every production line has unique requirements. That’s why our Re-Weigh Systems are highly customizable, offering flexible configurations to suit various product types, sizes, and production speeds. Whether you need to re-weigh individual packages, bulk items, or entire pallets, our systems can be tailored to meet your specific needs.

- Flexible Configurations: Adaptable to different product sizes, weights, and packaging formats.

- Scalable Solutions: Designed to accommodate growing production demands, with options for expansion and upgrades.

- Specialized Applications: Custom solutions available for unique industry requirements, such as high-speed operations or specialized weight ranges.

Compliance and Reporting for Regulatory Standards

Maintaining compliance with industry regulations is essential, particularly in sectors like food and pharmaceuticals where precise weight control is mandated. Our Re-Weigh Systems are equipped with comprehensive reporting and tracking features that help you stay compliant with all relevant standards. These features also provide valuable insights for continuous improvement in your production processes.

- Regulatory Compliance : Ensures your products meet all applicable weight regulations and industry standards.

- Detailed Reporting : Generates accurate reports for auditing, traceability, and quality assurance.

- Data Integration : Easily integrates with your existing data management systems for streamlined reporting and analysis.

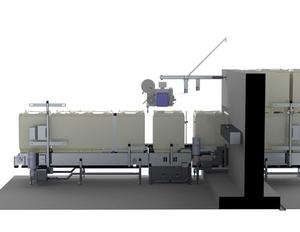

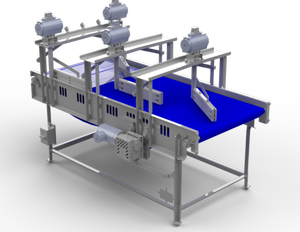

Equipment Gallery

Additional Information

Types

Bulk containers

Standard Features

Capabilities to integrate with customer’s systems to track information and keep within historian saved data for future use

Integrate with our automated de-stackers to reduce double handling by forklift operations

Quality

Maximize operator time and safety

Automated Solutions

Automated scanning and weighing

Optional Items

Combine with automated de-stackers/stackers

Pick-off stations