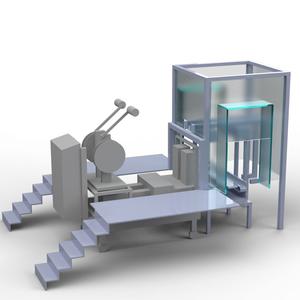

Banding & Strapping Equipment

Maximize throughput and minimize operator interaction with our quick operating autobander.

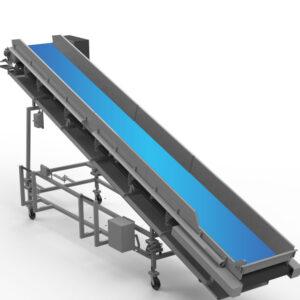

Category: Conveyors,Specialty Equipment,Robotics

Industry: Cheese/Dairy, Pizza/Bread, Fruit/Veggies, Meat/Poultry, Beverage, Pet Food, Packaging

Equipment Overview

Our Banding & Strapping Equipment is engineered to provide reliable and efficient solutions for securing products during transportation and storage. Whether you’re working in manufacturing, logistics, or packaging, our systems are designed to handle a wide range of materials and product sizes, ensuring that your goods are safely secured and ready for shipment. With a focus on durability, speed, and ease of use, our banding and strapping solutions help you maintain product integrity while optimizing your packaging process.

Advanced Banding Systems for Reliable Product Security

Our banding systems are ideal for applications that require secure bundling of products, whether it’s for storage, transport, or sale. Designed for precision and durability, these systems apply consistent tension to ensure that your products are tightly secured without damage. Whether you’re bundling pallets, boxes, or irregularly shaped items, our banding equipment delivers the performance you need to protect your goods.

- Consistent Tensioning : Ensures uniform banding across all products, reducing the risk of slippage or damage.

- Versatile Applications : Suitable for a variety of materials, including plastic, steel, and polyester bands.

- Automated Operation : Streamlines the banding process, reducing manual labor and increasing throughput.

High-Performance Strapping Systems

Our strapping systems are designed to provide high-strength securement for heavy or bulky items, making them ideal for industries that require robust packaging solutions. With options for both automatic and semi-automatic operation, our strapping equipment can be tailored to meet the specific needs of your production line, ensuring that your products are securely strapped and ready for the demands of shipping and handling.

- High Strength : Provides superior hold for heavy loads, ensuring that your products remain secure during transport.

- Flexible Configurations : Adaptable to various strap sizes and materials, including polypropylene and polyester.

- Quick Changeover : Easy-to-use controls and quick changeover features reduce downtime and keep your production line running smoothly.

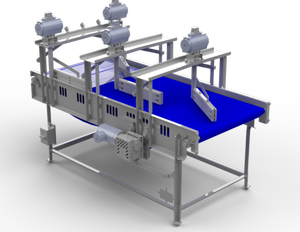

Automated Solutions for Maximum Efficiency

In today’s fast-paced production environments, automation is key to maintaining efficiency and reducing labor costs. Our automated banding and strapping systems are designed to integrate seamlessly into your existing production lines, providing consistent and reliable performance with minimal manual intervention. These systems are equipped with advanced technology to ensure precise operation, even at high speeds.

- High-Speed Operation : Capable of processing large volumes quickly, keeping up with the demands of high-throughput environments.

- Minimal Manual Intervention : Automation reduces the need for manual handling, lowering labor costs and the risk of injury.

- Seamless Integration : Easily integrates with existing equipment and processes, providing a smooth transition to automated banding and strapping.

Customizable Solutions for Your Specific Needs

Every industry has unique requirements when it comes to packaging and securing products. That’s why we offer customizable banding and strapping solutions that can be tailored to meet your specific needs. From the type of material used to the level of automation required, our systems can be designed to fit perfectly within your production environment, ensuring that you get the exact solution you need.

- Tailored Configurations : Customizable to accommodate different product sizes, shapes, and packaging materials.

- Scalable Options : Designed to grow with your business, with scalable solutions that can expand as your production demands increase.

- Industry-Specific Solutions : Specialized equipment and configurations available for industries with unique packaging challenges.

Durable and Reliable for Long-Term Use

Our Banding & Strapping Equipment is built to last, providing long-term reliability even in demanding industrial environments. With rugged construction and high-quality components, our systems are designed to withstand continuous operation, reducing maintenance requirements and ensuring consistent performance over time.

- Rugged Construction : Built with durable materials to withstand the rigors of daily use in industrial settings.

- Low Maintenance : Engineered for reliability with minimal maintenance requirements, reducing downtime and operational costs.

- Long-Term Performance : Designed for longevity, ensuring that your investment in banding and strapping equipment pays off over the long term.

Why Choose Our Banding & Strapping Equipment?

At Loos Machine & Automation we’re dedicated to providing packaging solutions that enhance your production efficiency while ensuring the safety and security of your products. Our Banding & Strapping Equipment is engineered to deliver reliable performance, ease of use, and adaptability, making it an essential part of any modern production line. Whether you’re looking to improve your packaging process or upgrade your current equipment, our solutions are designed to meet the demands of today’s industries while preparing you for tomorrow’s challenges.

Equipment Gallery

Additional Information

Types

Individual or bulk pack

Standard Features

Reduce labor costs

Auto band feed

Quality

Multiple lid presses for tight seal prior to banding

Precise engineering and fabrication

Automated Solutions

Customizable

UL approved

Optional Items

Removable or set in place