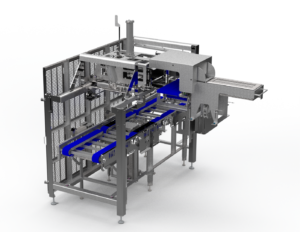

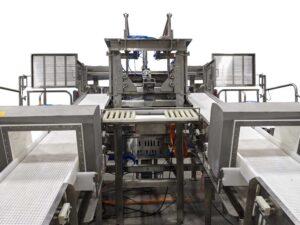

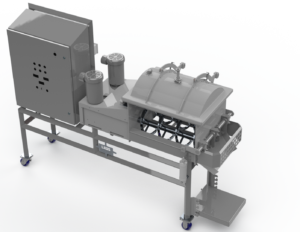

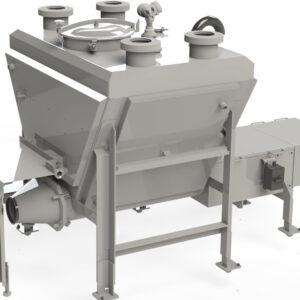

Collators

Loos Machine & Automation offers fully customizable collators that can be designed to fit your specific production needs. From simple product organization to complex, multi-layer collation, our systems provide the speed and accuracy necessary to keep your production running smoothly.

Category: Conveyors,Specialty Equipment

Industry: Cheese/Dairy

Equipment Overview

Loos Machine & Automation’s Collators are designed to organize and group products with precision and speed, ensuring streamlined production for high-volume operations. From food packaging to industrial components, our collators enhance efficiency by automatically arranging products for packaging, further processing, or distribution.

Efficient Product Organization

Our collators are built to handle a wide variety of products, ensuring they are neatly grouped and aligned for the next stage in your production line. Whether you need to organize products by weight, size, or count, our systems deliver reliable and consistent results, minimizing errors and reducing manual handling.

Types of Collators:

- Inline Collators: Ideal for high-speed production lines, these systems arrange products in single or multiple rows, preparing them for downstream packaging or processing.

- Layer Collators: Used to organize products into layers for stacking or palletizing, ensuring stability during transport or storage.

- Rotary Collators: Designed for circular or rotating systems, these collators provide continuous organization of products in a compact footprint.

- Custom Collators: Tailored to meet the specific needs of your production line, including unique product shapes, sizes, and materials.

Standard Features:

- High-Speed Operation: Capable of organizing products rapidly, ensuring continuous flow and reducing bottlenecks in the production process.

- Accurate Product Grouping: Sensors and precision controls ensure that products are consistently grouped and aligned to exact specifications.

- Durable Construction: Built with food-grade materials for sanitary environments, or industrial-grade materials for more rugged applications.

- User-Friendly Controls: Intuitive interfaces allow operators to adjust grouping patterns and monitor performance with ease.

- Compact Footprint: Designed to fit seamlessly into existing production lines without taking up excess space.

Automated Solutions:

- Automated Product Counting: Automatically counts products to ensure precise grouping, reducing the need for manual sorting and verification.

- Seamless Integration: Our collators can be integrated with upstream and downstream equipment such as conveyors, packaging machines, and palletizers for a fully automated production process.

- Recipe Management: Program multiple grouping patterns and quickly switch between them for different product runs, increasing production flexibility.

- Vision-Guided Collation: Optional vision systems ensure that only correctly grouped products are sent downstream, improving quality control.

Equipment Gallery

Additional Information

Types

Single or dual block infeed

Single vertical push or scissor lift style

Quality

Maximize plant space

Consistent product make

Minimal transfers and limited cheese loss

Performance

Single configuration up to 25,000 lbs/hr

Dual configurations up to 40,000 lbs/hr

Optional Items

Infeed metal detection

Light curtains