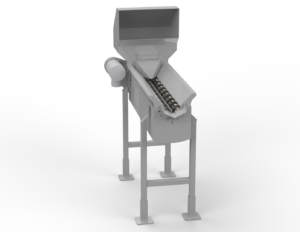

Product Singulator

Our Product Singulator is designed to streamline product flow by ensuring consistent and precise singulation of items in your processing line. Whether you’re handling raw ingredients, packaged goods, or delicate materials, our singulator offers reliable spacing to improve downstream operations, reduce jams, and maintain high-speed efficiency.

Category: Conveyors,Specialty Equipment

Industry: Cheese/Dairy, Pizza/Bread, Fruit/Veggies, Meat/Poultry, Pet Food

Equipment Overview

At Loos, we focus on delivering innovative solutions tailored to your specific needs. Our Product Singulator not only enhances efficiency but also adapts to the demands of your operation, providing unmatched reliability and performance in any application.

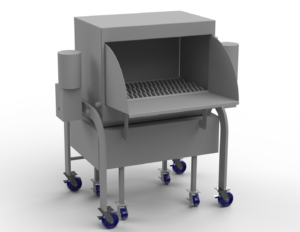

Key Features:

- Accurate Product Spacing: The singulator separates products to create a uniform gap between each item, optimizing for downstream packaging, labeling, and processing.

- Customizable Settings: Tailor the spacing and speed to fit your product specifications and production goals, ensuring seamless integration with your existing systems.

- Durable Construction: Built with robust materials to withstand the demands of continuous operation in various environments, from food processing to packaging.

- Easy Integration: Our system is designed for simple integration with conveyors, sorting systems, and automation equipment, providing flexibility across a range of applications.

- Reduced Downtime: Automated adjustments and low-maintenance components help keep your line running smoothly with minimal interruptions.

Applications:

- Food and Beverage Processing: Singulate items like cheese, meat, vegetables, or baked goods to ensure precision in portioning, slicing, or packaging processes.

- Pharmaceuticals: Manage delicate packaging and sorting tasks with ease, maintaining product integrity while increasing throughput.

- Consumer Goods: Improve the speed and accuracy of product handling for packaged goods, ensuring a smooth transition from production to packaging.