Tip/Tilt Press

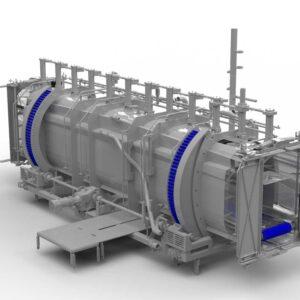

Our Tip/Tilt Press systems are designed to streamline the handling of heavy barrels and blocks in the dairy, cheese, and food processing industries. Built with precision and reliability in mind, our systems ensure the safe and efficient unloading of product with minimal operator intervention.

Category: Specialty Equipment

Industry: Cheese/Dairy

Equipment Overview

Loos Tip/Tilt Press systems are ideal for handling cheese blocks, dairy barrels, and other large containers in high-demand production environments. Whether you're unloading raw ingredients or preparing products for further processing, our equipment delivers consistency and reliability.

Key Features:

- Versatile Design: Accommodates various sizes of barrels, blocks, and drums, providing flexible handling for multiple applications.

- Automated Operation: Integrated automation for smooth and controlled tipping, tilting, and pressing processes, minimizing manual labor and increasing efficiency.

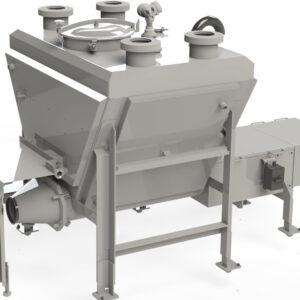

- Customizable Settings: Adjustable press force and tilt angles to suit specific product requirements, ensuring product integrity and optimal processing conditions.

- Sturdy Construction: Heavy-duty stainless steel construction designed to withstand rigorous industrial environments while ensuring hygiene and compliance with food safety standards.

- Easy Integration: Designed to seamlessly integrate with existing processing lines, allowing for smooth product flow and enhanced operational efficiency.

Equipment Gallery

Additional Information

Types

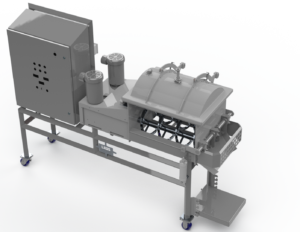

Pneumatic

Gear and motor actuated styles of tipping

Block tip presses include integral press heads

Barrel tip presses utilize loose press plates

Gear and motor actuated styles of tipping

Block tip presses include integral press heads

Barrel tip presses utilize loose press plates

Quality

Minimal whey waste and clean design

Washdown friendly

Washdown friendly

Automated Solutions

Adjustable pressing pressures and tip cycle times

PLC/HMI controls

VFD controlled conveyors

Adjustable pressing pressure

Recipe integration

Meets NEC, NFPA and ANSI codes

UL approved

PLC/HMI controls

VFD controlled conveyors

Adjustable pressing pressure

Recipe integration

Meets NEC, NFPA and ANSI codes

UL approved

Optional Items

Vacuum whey recovery systems

Enclosed CIP-able

Quick connect flow panels

Enclosed CIP-able

Quick connect flow panels