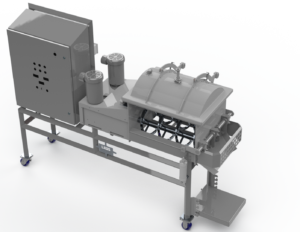

Tumble Drums

Our Tumble Drums are designed to deliver consistent mixing, gentle product handling, and optimal distribution for various food products, including cheese, vegetables, and other delicate items. Our innovative tumble drum systems are engineered for flexibility, ensuring your production process is both efficient and adaptable to your specific needs.

Category: Specialty Equipment

Industry: Cheese/Dairy, Pizza/Bread, Fruit/Veggies, Meat/Poultry, Beverage, Pet Food

Equipment Overview

No two operations are the same, which is why we offer fully customizable Tumble Drum systems to fit your unique production requirements. Whether you're integrating into an existing line or designing a new setup, our team works closely with you to ensure seamless integration and optimized performance.

Key Features:

- Precise Product Blending: The controlled, gentle rotation of our tumble drums ensures uniform blending and distribution without compromising product integrity.

- Hygienic Design: Built with food safety in mind, our tumble drums are made of stainless steel and feature easy-to-clean surfaces, meeting the highest industry standards.

- Versatile Applications: Whether you're handling shredded cheese, diced vegetables, or delicate foods, our tumble drum systems are designed to accommodate a wide variety of products.

- Durable Construction: Engineered to withstand rigorous daily operations, our tumble drums are built for longevity, reducing downtime and maintenance costs.

- Automated Efficiency: Our systems are fully customizable with options for automated infeed, outfeed, and continuous production flows, enhancing your throughput while minimizing manual intervention.

Customized Solutions for Your Production Line

No two operations are the same, which is why we offer fully customizable Tumble Drum systems to fit your unique production requirements. Whether you're integrating into an existing line or designing a new setup, our team works closely with you to ensure seamless integration and optimized performance.

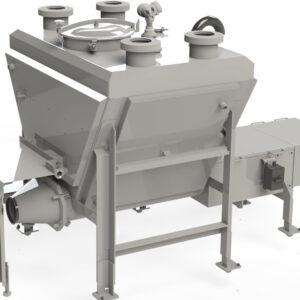

Equipment Gallery

Additional Information

Performance

Integrate with single-line systems

Blend and batch systems for required throughputs

Blends for spices and other ingredient additions

Automated Solutions

Ingredient delivery

Meets NEC, NFPA, and ANSI codes

UL approved

Vision capabilities (precise knowledge of cut size/weights)

Unlimited recipe integration provided

Safety assessed and category rated

Optional Items

Single or twin screw for both ribbon or paddle design

CIP-able

Jacketed auger and shell

Load cells for precise recipe management

Multiple ribbon styles for different products and throughput

Variety of automated conveyance solutions between operations

Optional lid slide to allow for low head clearance

Types, Styles and Features

Cheese, meat, and poultry industries

Stainless steel construction with 316 product contact

Various sizes available to accommodate required throughputs

End gate options to easily discharge product

Meets WDA, FDA, and USDA standards

WDA approved sanitary design front and rear shaft seals

Stainless steel bearing design