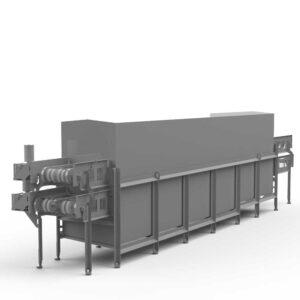

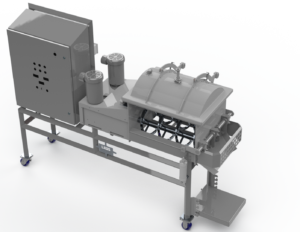

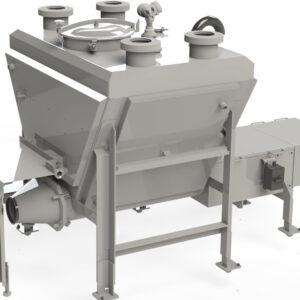

Wash Systems

Our robust Wash Systems are designed to provide thorough cleaning for a wide range of food processing applications, ensuring compliance with industry hygiene standards while reducing downtime and labor.

Category: Process

Industry: Cheese/Dairy, Pizza/Bread, Fruit/Veggies, Meat/Poultry, Beverage, Pet Food

Equipment Overview

Every production facility has unique cleaning requirements, and our Wash Systems are built with flexibility in mind. Whether you're processing dairy, cheese, or other food products, we tailor our equipment to meet the demands of your specific operations. From high-pressure rinse systems to automated cleaning cycles, our solutions offer the right combination of technology and performance to keep your equipment operating at its best.

Key Features of Our Wash Systems:

- Sanitary Design: Constructed from high-grade stainless steel and designed with smooth surfaces and minimal crevices, our systems prevent bacterial buildup and ensure easy cleaning.

- Automated Cleaning Cycles: Reduce manual intervention with programmable wash sequences that offer repeatable, consistent results.

- Efficient Water and Energy Use: Our wash systems are optimized to reduce water and energy consumption without compromising on cleaning power.

- Custom Configurations: Each system can be adapted to handle various equipment sizes and types, including conveyors, cutting tools, and containers.

- Safety-First Approach: Built with safety in mind, our systems include protective barriers, emergency stop functions, and easy-to-use controls to ensure a safe operating environment.

Why Choose Loos Machine & Automation Wash Systems?

With years of experience serving the food processing industry, Loos Machine & Automation has developed wash systems that are both durable and efficient. Our solutions are designed to meet the highest standards of cleanliness while ensuring minimal downtime in your operations. From custom design to installation and ongoing support, we’re committed to delivering solutions that enhance productivity and food safety.

Equipment Gallery

Additional Information

Types

Stand-alone cabinet

Multiple compartment

Standard Features

Can be designed to meet any desired feed rate required

Integrates to your CIP system with ease

Includes high pressure spray nozzles

Replaces COP system

Automatic equipment de-nesters available

Consistent safe application utilizing safety switches and guarding

Batch or continuous options available

Automated Solutions

Chemical dosing systems and monitoring systems

RTD, heat and fluid level monitoring

CIP system integration

Operator control panels

Meets NEC, NFPA and ANSI codes

UL approved

Optional Items

De-nesters