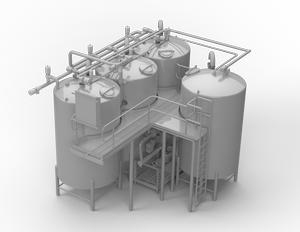

CIP & COP Systems

Loos Machine & Automation's CIP (Clean-In-Place) and COP (Clean-Out-of-Place) systems are designed to meet the rigorous hygiene and sanitation requirements of the food and beverage industry. These systems are crucial for maintaining the cleanliness of processing equipment without disassembly, ensuring product safety, and optimizing operational efficiency.

Category: Process

Industry: Cheese/Dairy, Pizza/Bread, Fruit/Veggies, Meat/Poultry, Beverage, Pet Food

Equipment Overview

Loos Machine & Automation's CIP (Clean-In-Place) and COP (Clean-Out-of-Place) systems are designed to meet the rigorous hygiene and sanitation requirements of the food and beverage industry. These systems are crucial for maintaining the cleanliness of processing equipment without disassembly, ensuring product safety, and optimizing operational efficiency.

CIP (Clean-In-Place) Systems:

- Automated Cleaning : CIP systems at Loos Machine & Automation are engineered for automated, repeatable, and controlled cleaning processes, which reduce the need for manual labor and minimize downtime.

- Customizable Solutions : The systems can be customized to accommodate a wide range of equipment, including tanks, pipelines, conveyors, and other processing equipment. They can be tailored to specific operational needs, ensuring that all areas are thoroughly cleaned.

- Efficient and Effective : By using precisely controlled cleaning parameters such as temperature, flow rate, and chemical concentration, CIP systems effectively remove soil, bacteria, and other contaminants, ensuring compliance with industry standards.

- Sustainability : These systems are designed with water and energy efficiency in mind, reducing the environmental footprint of the cleaning process.

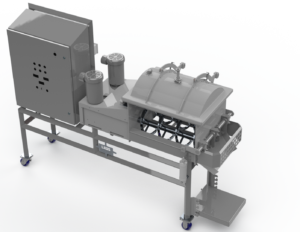

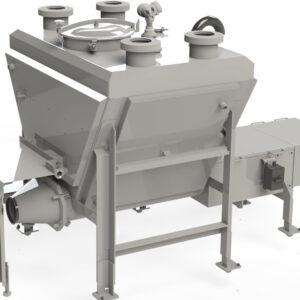

COP (Clean-Out-of-Place) Systems:

- Thorough Cleaning : COP systems are ideal for equipment components that need to be disassembled for cleaning. Loos Machine & Automation offers solutions that ensure these parts are thoroughly cleaned and sanitized.

- Ease of Use : The systems are designed to simplify the cleaning process, allowing for easy loading and unloading of components. This helps reduce the risk of operator error and ensures consistent cleaning performance.

- Versatile Applications : COP systems can handle a wide variety of parts and equipment, making them suitable for different industries and applications. They are especially useful for cleaning parts that are challenging to clean in place due to their complexity or size.

Both CIP and COP systems from Loos Machine & Automation are built with a focus on durability, ease of maintenance, and compliance with industry regulations, making them a reliable choice for maintaining hygiene standards in food processing and other industries.

Equipment Gallery

Additional Information

Types

Multi-circuit offerings

Individual stainless steel tank for COP

Standard Features

Integrated belt lift designs for ease of conveyance cleaning

High-pressure nozzles for COP

Quality

Heavy-duty construction

Performance

Custom recipes for plant-specific needs

Precise time, temperature, and chemical regulation

Automated Solutions

Meets NEC, NFPA, and ANSI codes

UL approved

Custom recipes

Plant integration

Parameter tracking & recording

Custom tagging options

Optional Items

Valve clusters

Pumps